Social and Ethics Committee report and sustainability

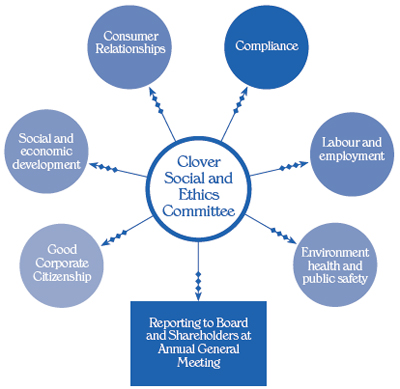

The report of this new Board committee (previously the Sustainability Committee) incorporates both the requirements of the Companies Act, 71 of 2008 (the Act) in terms of regulation 43, as well as the King Report on Governance for South Africa (2009) ("King III") regarding responsible corporate citizenship. This report also deals with sustainability matters deemed material by the Board as previously reported by the Sustainability Committee.

1. Introduction

In terms of regulation 43 of the Act, the Group subscribes to the “enlightened shareholder value approach” – this approach requires that directors are obliged to promote the success of Clover in the collective best interest of stakeholders, which includes, as the circumstances dictate, Clover’s needs to take account of the relevant interests of among others, the community, employees, customers and suppliers. Clover is one of the few South African businesses that have been in existence for well over 100 years. It recognises that in order to survive and prosper, critical self-assessment and constant change are required. The Group’s sustainability strategy is also based on the acknowledgement of its responsibility to all stakeholders in order to ensure its long-term viability.

The committee is chaired by the Lead Independent Director of the Board and consists of four members who meet on a regular basis. The committee is a sub-committee of the Board and will, through one of its members, report to the shareholders at the Company’s Annual General Meeting on all matters within its mandate. It ensures open communication with other committees in order to ensure consistent behaviour from a social and ethics point of view. The committee has developed and adopted a formal work plan entailing the functions of the committee as set out in regulation 43 of the Companies Act in terms of which the committee prioritised the implementation of certain actions to enable the committee to fully discharge its statutory functions over a period of three years. This committee assumes the responsibility to ensure that the Board sets the appropriate tone, and that the behaviour and messages of the Board and the directors support and contribute to Clover’s ethical corporate culture. This report sets out the achievement of the committee in the first year of its establishment.

Over and above the requirements of the Act, the scope of the report has also taken into consideration the Sustainability Reporting Guidelines of the Global Reporting Initiative. In short, it attempts to summarise the key aspects of Clover’s business that are critical to its long-term future.

2. Scope

The scope of this review currently covers its South African operations and will over time be extended to its subsidiaries in other countries.

Assurance on this report

While King III also requires that sustainability reporting should be independently assured, the committee is of the opinion that it would be premature to obtain external assurance until the Group’s recording systems are mature. Clover has put in place processes to ensure compliance to all applicable legislation and/or legal requirements. It is, however, the Group’s intention to expand on qualitative and quantitative information as systems are progressively bedded down. Major improvements in this regard were made during the year under review, specifically with regard to Clover’s employment equity plan, employee training and development, the formalisation of the Group’s social and ethics policy as well as its policy on environmental impact.

It is the Group’s intention to further incorporate prevailing codes of best practice in terms of Regulation 43 (Regulations to the Companies Act). While these processes are being matured, the Social and Ethics Committee has monitored Clover’s activities with regard to matters relating to:

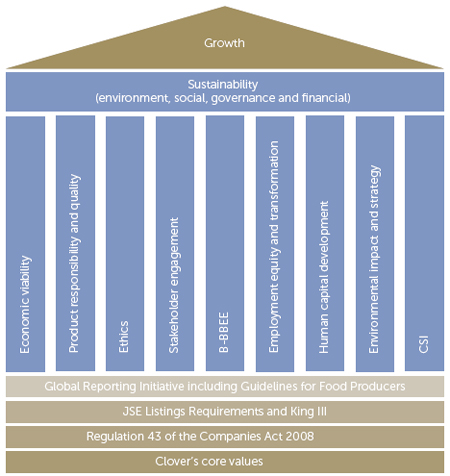

3. Clover’s pillars of sustainability

Clover’s sustainability hierarchy and drivers:

The sustainability issues considered material to the group and which are set out in this review are as follows:

3.1 Economic viability

The Group recognises that its continued existence and prosperity depends firstly on its economic viability. To this end in 2010 it approved a major expansion and optimisation project of its production and distribution facilities to be carried out over a four-year period. These changes will require a substantial investment and will position the Group well to improve its service offering to South African customers for several years ahead.

Economic indicators of sustainable development

| Sustainable development indicator overview | 2012 | 2011 | 2010 | 2009 | 2008 |

|---|---|---|---|---|---|

| Revenue (R’m) | 7 223,9 | 6 542,3 | 6 161,5 | 5 475,8 | 5 718,3 |

| Operating profit (R’m) | 371,2 | 319,0 | 559,0 | 664,3 | 297,2 |

| Earnings per ordinary share (cent) | 114,6 | 116,7 | 214,0 | 22,3 | 5,2 |

| Equity dividends paid per ordinary share (cent) | 30,0 | 43,0 | – | 1,1 | 0,7 |

| Dividends paid per preference share (cent) | 24,6 | 23,9 | 24,9 | 37,3 | 35,2 |

| Headline earnings per share (cents) | 116,0 | 113,8 | 33,1 | (82,2) | 150,2 |

3.2 Product responsibility and quality

Clover’s commitment to quality starts on the farms of its producers. The Group has developed and introduced its own Best Farming Practices (“BFP”) programme for its milk producers, based on the International Dairy Federation’s (“IDF”) directive.

Clover’s BFP programme includes the following aspects:

- Animal health and herd management.

- Animal feed and water.

- Animal medication and agricultural chemicals.

- Milk hygiene and safety.

- Environmental management.

- Personnel and people.

- Treatment and hygiene registers.

- Required records and registers.

- Archives.

Since the end of June 2009, 100% of the Group’s milk producers have participated in the BFP programme and all new producers sign up as they join Clover. Compliance is assured through regular audits and the producers who passed the audits with 80% or more, represented 98.81% of Clover’s milk intake at the end of June 2012.

As mentioned previously, Clover has embarked on broadening the application of the BFP programme by integrating the most recent drivers as part of a global shift towards sustainable dairy farming. Being a relatively complex structure that requires a certain level of expertise, Clover postponed the implementation date to 1 January 2013 as it builds capacity to prudently phase in and manage the system. Globally, this is still a developing area of business and Clover will learn and grow with the rest of the world, as sustainable dairy farming evolves to maturity.

The preliminary focus areas for the Clover Sustainable Dairy Model (“CSDM”) are:

- Herd management, including the management of greenhouse gas (“GHG”) emissions.

- Animal feed, pasture and soil management, including GHG emissions and retention.

- Water management and treatment.

- Animal medication and agricultural chemicals.

- Dairy parlour and equipment (including infrastructure, hygiene and safety).

- Milk composition and quality.

- Environmental management, manure handling and bio-diversity, including GHG emissions and the reduction thereof.

- Energy management and utilisation of alternative energy resources for the reduction of GHG emissions.

- Bio-security, with the main focus on disease control.

- Personnel and people.

The required records, registers and archives will form an integral part of the above focus areas as this will no longer be in hard copy format, but electronically. The Group stays in close contact with international work groups and uses the IDF’s directive as base and benchmark for this integration.

During the period under review, Clover introduced its Electronic Tanker Collection System (“ETCS”) to all vehicles collecting raw milk.

In short, the ETCS system:

- Measures the milk volume with flow metre technology, as it is pumped from the bulk tank on the farm into the Clover tanker. This information will be transferred electronically via cell phone technology to Clover’s milk system.

- Electronically takes a flow proportional, representative sample of the milk. These samples are then sent to Lactolab’s fully-equipped laboratory to assess the composition and quality of the milk.

- Electronically monitors the temperature of the milk as it is pumped from the bulk tank into the Clover tanker. This information will also be transferred via cell phone technology to Clover’s milk system.

This is a first for the dairy industry in South Africa and apart from its cost saving and productivity benefits, ensures that Clover and its producers have peace of mind that Clover is purchasing its raw milk according to world-class standards and with minimum human intervention. Although there are still a few issues to attend to, the Group is confident that this system holds great value for Clover and its producers in the long-term.

Product quality

Clover’s business strategy as a branded foods and beverages group with a strong emphasis on value-added products is based largely on the quality of its products. Product quality relates directly to brand strength and indirectly leads to price elasticity.

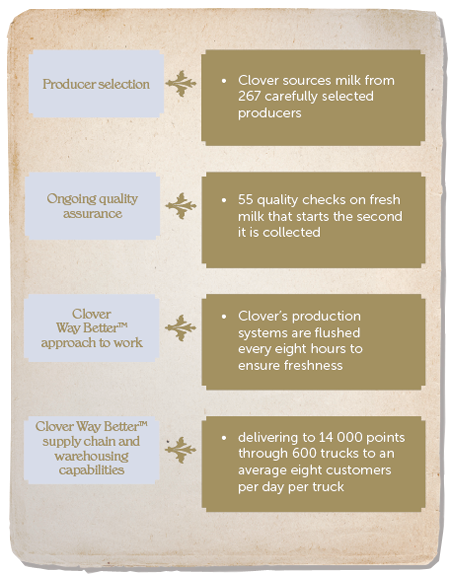

The Clover Way Better™ initiative incorporates a consistent approach to ensure continuous quality that starts with the selection of its producers and continues throughout the production process. The salient features of the Way Better™ initiative are:

Some of the industry recognition listed below is demonstrative of Clover’s commitment to the consistent quality of its products:

| Product | Award |

|---|---|

Fresh milk |

|

| PMR Africa – Golden Arrow 2012, National Survey of

FMCG Manufacturers: first overall

Icon Brands 2012: second in the Beverages category PMR Awards: Diamond Award for fresh dairy |

|

Pre-packed cheese |

|

| PMR Africa – Golden Arrow 2012, National Survey of

FMCG Manufacturers: first overall

Icon Brands 2012: third in the Dairy category Qualité Awards 2012: Clover Cheddar |

|

Feta cheese |

|

Agri Expo SA Dairy Championships 2012:

|

|

Elite cheese |

|

Agri Expo SA Dairy Championships 2012:

|

|

Butter and butter spreads |

|

Agri Expo SA Dairy Championships 2012:

|

|

Tropika |

|

| PMR Awards: Diamond Award for Most Successful

Campaign in past 12 Months

Bronze Apex award for taking the brand performance to the next level Sunday Times “Top Brands” second in Fruit-based category |

|

Krush |

|

| PMR Awards: Diamond Award for Most Successful Product

Launch in Past 12 Months

Sunday Times “Top Brands” first in Fruit-based category |

|

3.3 Ethics

Clover is committed to achieving its business goals with integrity, high ethical standards and in compliance with the law. The Group’s ethics policy sets out principles and expectations to help employees conduct business in a way that is honest, ethical, lawful and above reproach. The policy applies to all Clover employees, managers and directors. It also relates to Clover’s conduct with its stakeholders and applies to relationships with subcontractors, suppliers, customers, shareholders, bankers, joint venture partners, etc.

Violations of the policy may be grounds for disciplinary action, including termination of employment or termination of Clover’s relationship with a stakeholder.

In instances where the employee wishes to remain anonymous, the employee may direct his/her concerns to Clover’s Ethics Line “Tip-Offs Anonymous”, which can be reached on a 24-hour basis. Allegations of unethical behaviour are then made available to executive management and to the Group Risk Manager, who would ensure that a diligent investigation process be followed to confirm or refute allegations.

A copy of Clover’s ethics policy is available on the Group’s website at www.clover.co.za.

3.4 Clover’s stakeholders

Throughout the 2012 financial year the Group has actively engaged with all its key stakeholders. Management undertakes to identify all stakeholders as well as their legitimate interests in and expectations of the Group on a continuous basis as stakeholders’ interests in the Group are dynamic and subject to change. Once stakeholders are identified, management decides through consultation with the various stakeholder groups how to further engage with each constituency.

This process forms part of the Group’s risk management framework.

| Stakeholder | Why engagement is important | Types of communication | Frequency | |

|---|---|---|---|---|

| 3.4.1 | Milk producers | To ensure security of Clover’s milk producers | Circulars, regional individual and group meetings with producers, media and the Clover producers forums | Ongoing |

| 3.4.2 | Employees | To ensure that staff are updated on business information and strategy to enhance individual contribution and Company objectives | Intranet, Ce briefs, management briefs, general

staff briefings, (In Clover) bi-monthly newletter, workshops and conferences, notice boards |

Ongoing |

| 3.4.3 | Trade unions | To engage organised labour on matters affecting their members as well as matters of mutual interest | Regular union meetings and collective bargaining forums | Ongoing |

| 3.4.4 | Principals (Danone SA, Unilever, Foodcorp, Orley Foods and Epic Oil) | To ensure that there are clear channels of communication | Contract and service level agreements | Monthly and/or quarterly |

| 3.4.5 | Business partners | To ensure that Clover has the support of local industry suppliers | Meetings | Ongoing |

| 3.4.6 | Shareholders, investors and analysts | To ensure that Clover communicates delivery on strategy, financial performance and capital expansion plans | Presentations and meetings, circulars to shareholders, the Intregated Annual Report, the Annual General Meeting, SENS announcements, jse show cases, the media | Ongoing, except in the closed periods. Formally twice a year as required by the jse |

| 3.4.7 | Government and regulators | To ensure that Clover can provide input on policy changes in the agricultural sector, food security and general information | Meetings, written and verbal communication | Ongoing |

| 3.4.8 | Media | To ensure that there is interaction on strategy, capital expansion programmes, financial results, and to deal with issues that concern stakeholders at large | One-on-one and group interviews, site visits, media statements and general interaction | Ongoing |

| 3.4.9 | Communities, traditional and civic society | To ensure that Clover’s environmental strategy is enabled through community empowerment | Direct interaction through various csi and environmental campaigns in various communities | Ongoing |

| 3.4.10 | Trade | To ensure that there is regular interaction relating to promotional activities, performance reviews and annual trading terms negotiations | Meetings, conferences and workshops | Bi-monthly |

| 3.4.11 | Consumers | To ensure that Clover has direct consumer interaction and feedback | Promotions and community based initiatives | Ongoing |

3.4.1 Milk producers

Clover’s roots date back to 1898, when a group of milk producers in KwaZulu- Natal saw the need to market their milk collectively through products with a longer shelf life, such as butter. Through the years, the then National Cooperative Dairies and what later evolved to become Clover maintained a very close relationship with its milk producers which sustained a continuous supply of raw milk to the Group.

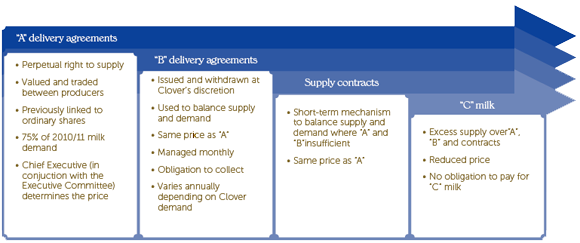

Clover’s conversion from a cooperative to a commercially driven, viable entity

necessitated a paradigm shift in the organisation’s focus, from being a supply

driven to a demand driven company. In order to establish some equilibrium

between producer supply and market demand, Clover implemented its

Unique Milk Procurement System (“CUMPS”). CUMPS offers producers

certainty that the milk they contractually produce will be acquired by Clover

at a predetermined price. At the same time it offers Clover the ability to match

its raw milk intake with market demand for its product. Through CUMPS,

Clover mitigates volume risk with regards to its raw milk supply. It also supports

the company’s strategy of being a brand driven organisation with a focus on

value-added products as it is exiting the low margin bulk commodity market

internationally used for balancing an oversupply of raw milk.

Despite significant volatility and market changes during the review period, Clover’s aggregate raw milk supply exceeded its needs by only 1.82% for the review period (including a 1% provision for raw milk losses).

A direct benefit of CUMPS is assuring stable and economically viable rural communities, including a strong base of milk producers. This will significantly contribute to the sustainability of agriculture in general, and specifically sustain a continuous supply of raw milk to the Group and support food security within the country.

Clover is one of a few large dairy processors that have purchased milk from previously disadvantaged producers for many years. Economic factors and sustainable milk quality make it very challenging for these enterprises to survive. Likewise, a number of BEE initiatives failed as a result of lack in expertise, support and dedication at farm level. There are, however a number of very good examples of commercial producers partnering with communities and labourers. Most of these projects were initiated by Amadlelo Agri and are sustainable.

Clover assisted the Fort Hare project by purchasing the raw milk and subsidising the transport costs thereof by R588 000 from October 2007 to May 2010, when the project reached sustainability. Middeldrift followed and the transport cost in this instance was subsidised by R376 000 for the period November 2008 to May 2010. Similar projects were developed at Keiskammahoek and Shiloh. The milk from these four farms accounts for almost 11% of Clover’s milk intake in the Eastern Cape region.

| Description | 2012 | 2011 | 2010 | 2009 | ||||

|---|---|---|---|---|---|---|---|---|

| Number of milk producers who supplied milk to Clover during the year | 267 | 293 | 309 | 353 | ||||

| Estimated number of employees employed by above producers* | 3 738 | 4 102 | 4 326 | 4 942 | ||||

| Estimated number of dependents reliant on income received from above employees** | 18 690 | 20 510 | 21 630 | 24 710 | ||||

|

||||||||

The downward trend in the Group’s milk producer numbers is the result of continuous consolidation in the primary industry and should not be interpreted as a threat to the sustainability of milk supply in the short- to medium-term. It is, however, not in the best interest of rural development or job creation in South Africa and it’s therefore important for the industry and government to find a way of ensuring a viable agricultural sector and dairy industry.

3.4.2 Employees

Recognising that its future success depends on the quality and loyalty of its people, the Clover Group strives to create a pleasant, healthy and motivating work environment where employees and are treated fairly and, through focused training and development programmes and are equipped with the skills they require to perform optimally. It supports the principles of employment equity and mobilises an effective social responsibility programme focusing on education, health and skills development.

To this effect, the Group actively promotes and supports various employee initiatives to foster a positive work climate across departments and divisions. A special effort is made to align individual and team contributions to Company.

Channels of communication to embed a common vision and ensure alignment include: The In Clover staff publication, the intranet, management briefing sessions, shop steward meetings, mission directed work teams and departmental meetings.

3.4.3 Trade unions

Approximately 55% of Clover’s staff is unionised with membership of the Food and Allied Workers’ Union (“FAWU”) and the South African Commercial, Catering and Allied Workers Union (“SACCAWU”). Collective bargaining takes place at national level and the Group interacts across a range of labour forums to ensure sound employee relations and compliance with legislation and recognised labour practices.

Wage negotiations during the period under review ended in a dispute which remained unresolved despite numerous attempts to find a solution. Subsequent to the reporting date, FAWU served notice on the company of their members’ intention to strike in pursuit of their wage demands, with the protected strike commencing on 18 July 2012. Clover obtained an interdict preventing members of FAWU to be involved in incidents of violence, intimidation and/or causing damage to property.

At the time of writing, the company successfully completed wage negotiations for the period to 30 June 2013, settling on a 8.5% wage increase and a minimum payroll increase of R360 (representing a 10.5% increase for the lowest paid worker).

3.4.4 Principals

Clover distributes products for various principals, namely Unilever, Eskort, Foodcorp, Danone SA, Orley Foods and Epic Oils. The principal business is strategically important to Clover and enables Clover to optimise the efficiency of the distribution network, increase the profitability of the distribution platform for Clover’s own products and provides Clover with critical mass to service markets, which its competitors cannot economically service.

Given the increase in input costs such as fuel and fleet maintenance, workforce management and training as well as environmental impact considerations, the value proposition for principals to outsource the distribution and merchandising of their products to a supply chain specialist such as Clover is compelling. Clover’s dairy business is the ideal enabler to reach a widely dispersed customer and consumer base.

In the financial year ended 30 June 2012, Clover handled approximately 328 000 tonnes of principal products for its principals, totalling approximately R6,01 billion in principal turnover. Clover is remunerated on a “cost plus” fee basis with fees tied to the volume of products distributed or on a percentage of turnover basis.

Clover has successfully renegotiated a further two year contract with Danone and five year contracts with Unilever, Foodcorp, Eskort and Orley Foods. The objective has always been for Clover to partner with principals that enhance and compliment the product and service offering of Clover to its customers.

These contracts are not only profitable for Clover, but offer extensive benefits to both principals and customers, offering a world-class distribution and sales service with the added benefit of economies of scale.

The table below sets out the products handled and services provided to Clover’s principals:

| Products handled | Services rendered | |

|---|---|---|

| Unilever | All refrigerated products, being margarine (Rama, Stork,Flora and Meadowlands) | Warehousing and distribution services, manufacturing of OLA ice cream, sales and merchandising services |

| Danone SA | Total product basket, being custard, yoghurt and maas | Supply chain planning, distribution and warehousing, raw material procurement, credit control and debtors admin, manufacturing and packaging of maas and custard, IT services, sales and merchandising services |

| Eskort | Total product basket, being processed pork products | Sales and merchandising services, distribution services, credit control and debtors admin |

| Foodcorp | Mageu, being fermented maize drink | Manufacturing, packaging and distribution, credit control and debtors admin, sales and merchandising services |

| Orley Foods | Orley Whip Cream | Sales and merchandising services, distribution services, credit control and debtors admin |

| Epic Oils | Margarine (Canola and Blossom) | Sales and merchandising services, distribution services, credit control and debtors admin |

3.4.5 Business partners

Clover recognises that well-aligned partnerships are strategically important to build or springboard a business to heightened levels of success, or to inject the energy required to enter a new era of profitability. Clover is not oblivious to the contribution its various business partners have made to its success. A large number of these partnerships have been established in some of the most testing times in Clover’s long history and are based on open and honest communications, based on the principles of fairness and mutual success.

3.4.6 Shareholders, investors and analysts

Clover was successfully listed on the JSE Limited on 14 December 2010, raising R575 million in a private placement that was oversubscribed. Shareholders include milk producers, staff, the directors of Clover, individuals and a number of South Africa’s largest institutional investors. International institutions have also showed an increasing interest in Clover’s investment case.

Clover engages with its shareholders on a regular basis through financial results presentations and road shows, media commentary, Stock Exchange News Service announcements, its annual report and other regulatory circulars to shareholders. In addition, Clover hosts investor site visits and open days to elaborate on its capital expansion programme and strategy.

3.4.7 Government and regulators

Competition Commission

Clover remains committed to fully co-operating with the Competition Commission and takes reasonable steps to ensure that management and employees do not engage in conduct that would constitute a prohibited practice. No instances of prohibited behaviour were investigated by the Competition authorities during the year under review.

The Group established a Competition Law Centre of Excellence (“CLCE”) in conjunction with the KPMG Competition Law Advisory Practice early in 2012. In general, the CLCE is a critical management tool developed by the Group to ensure a high standard of ongoing competition law compliance within the Group. The CLCE allows for a seamless interaction between the members of the Group’s legal department the members of the KPMG Competition Law Advisory Practice, which offer both competition law and competition economics support and advice. More information on CLCE is available in the Corporate Governance Section of this Integrated Report.

Consumer Protection Act ("CPA")

The Group has taken proactive steps to ensure that it is fully prepared for the application of the Consumer Protection Act, which came into effect during the previous reporting period. High-level induction programmes to key individuals in the Group on the potential effect of the application of the new Consumer Protection Act are ongoing. The process of establishing a Consumer Protection Act Centre of Excellence, similar centre to the CLCE is in progress.

No material complaints or investigations were received during the review period.

3.4.8 Media

Clover views the media as an effective channel to communicate with external stakeholders and strives to maintain open, honest and effective communication. The Group regularly comments on the factors and developments that impact on Clover’s business activities, as it believes that the public should have a balanced view of its industry.

Communication is generally pro-active in the form of one-on-one meetings, group presentations, media statements, voluntary releases through the JSE’s Stock Exchange News Service, updates as well as site visits. Relevant information is continuously updated on the Group’s website, www.clover.co.za.

3.4.9 Communities, traditional and civic society

Cover’s engagement with and responsibilities to the communities in which it operates and on which its products impact are discussed in the corporate social investment and environmental strategy section.

3.4.10 Trade

Cover’s aim is to cultivate strong growth with trading partners by being more than just a vendor. We understand shopping behaviour and try to add value by assisting the trade to effectively meet the consumers’ expectations.

3.4.11 Consumers

The Group’s strong and honest relationships with its consumers, principals, retail and wholesale businesses, agents and distributors, continued during the year under review. This ensures that the Group’s products reach consumers throughout South Africa in good condition and at market related prices in a very competitive market. Clover’s emphasis on quality products is strongly embedded in the quality raw milk which the Group procures from its producers.

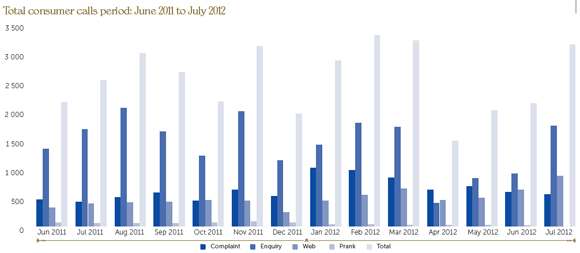

The Clover Consumer Centre (“CCC”) strives to consistently service our customers’ expectations and needs by demonstrating the required respect for their needs and opinions. All complaints and enquiries are handled professionally by trained consultants to ensure that the image of Clover, Clover’s brand names and services are protected while ensuring compliance with the Consumer Protection Act.

As per the Consumer Protection Act, a procedure is in place and will be applied in situations where a serious risk or threat exists for Clover in general, Clover’s brand names or products, Clover’s personnel or on possible environmental impact. From all the priority calls received in the period mentioned below, 0,1% were escalated to the Crisis Committee and/or the Executive Committee (priority 1 calls), 4,8% to management (priority 2 calls) and 95,4% were handled by the consumer consultants (priority 3 and 4 calls).

Priority calls: classification

| Type of call | Description |

|---|---|

| Priority 1 | Critical calls Compliant which can:

|

| Priority 2 | Client request feedback in writing The complaint receives urgent attention and the consumer is kept informed by the head of the Consumer Centre until such time as the investigation is completed and complies with the requirements of the consumer. |

| Priority 3 | Client wants to speak with manager Complaints, which are not satisfactorily dealt with by the consultant and where the consumer insists on communicating with the head of the Consumer Centre, the complaint must be escalated to her for her attention. |

| Priority 4 | Completed by consultants Complaints are attended to by the consultant with the information at hand and no further escalation of the complaint/ incident is necessary. |

Consumer engagement and the Way Better philosophy

Clover’s corporate strategy is to build onto existing competencies within the Group and to establish a culture of exceptional performance with a view to creating a platform for future market expansion. Key to all of Clover’s activities is the expansion of capacities to share in the strong growth in consumption in the product segments in which it has a leading market share.

Clover has identified a unique set of strategic pillars as disclosed on page 6 on which the success of the business is founded. The philosophy behind the Way Better initiative is therefore more than a marketing campaign. It represents a cultural step-change in seeking optimal ways of delivering on the corporate strategy and is aimed at setting new standards in best practice and to attract the best in the industry to Clover.

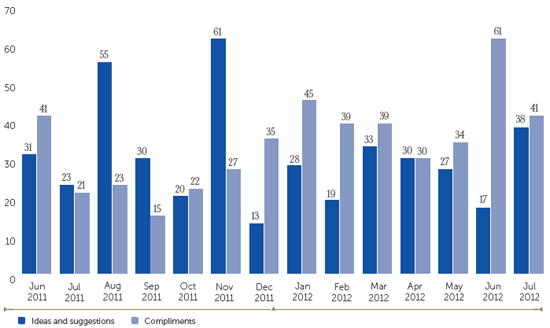

The Way Better metaphor was created in order to engage and introduce Clover’s consumers to this enhanced approach to doing business. Although primarily a marketing campaign, Clover Way Better™ draws on Clover’s position as a market leader that innovatively adds value through convenience and quality as highlighted by the number of ideas and compliments that we received during the year.

Ideas and compliments: period June 2011 to July 2012

| General information | Total: June 2011 to July 2012 |

|---|---|

| Number of compliments received | 473 |

| Ideas and suggestions | 425 |

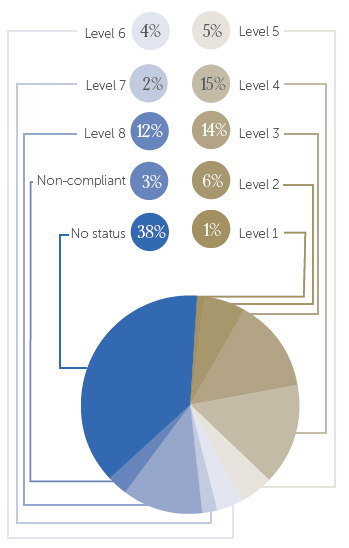

4. Broad-based black economic empowerment (B-BBEE)

Through preferential procurement, the Group concentrates on social and environmental issues in the supply chain. Approximately 62% of the money spent by the Group in its non-milk procurement process is spent with suppliers who enjoy various levels of B-BBEE compliance status.

| Value 2011/2012 |

Recognition | Weighted BEE procurement (2011/2012) |

Total value spend 2011/ 2012 |

|

|---|---|---|---|---|

| B-BBEE level | R | % | R | % |

| Level one | 48 276 323 | 135% | 74 387 682 | 1,3% |

| Level two | 228 723 900 | 125% | 325 276 211 | 6,1% |

| Level three | 530 061 588 | 110% | 614 123 220 | 14,1% |

| Level four | 569 403 218 | 100% | 604 829 949 | 15,2% |

| Level five | 182 072 425 | 80% | 180 328 210 | 4,9% |

| Level six | 154 592 569 | 60% | 94 912 735 | 4,1% |

| Level seven | 63 685 013 | 50% | 32 256 892 | 1,7% |

| Level eight | 446 738 947 | 10% | 51 550 520 | 11,9% |

| Sub total | 2 223 553 983 | 1 977 665 419 | 59,3% | |

| Non-compliant | 114 694 119 | 0% | 0 | 3,1% |

| No status | 1 414 076 928 | 0% | 0 | 37,7% |

| Sub total | 1 528 771 047 | 0 | 40,7% | |

| Total | 3 752 325 032 | 1 977 665 419 | 100,0% |

Clover views B-BBEE as an opportunity to increase economic activity, thereby creating:

- Sustainable livelihoods for as many of the country’s inhabitants as possible.

- A growing and sustainable consumer market.

Clover remains committed to the B-BBEE process as outlined by the Department of Trade and Industry. During the recent external audit (conducted by SANASapproved Empowerlogic), Clover received a Level 6 rating.

Preferential procurement spend with suppliers classified according to their BEE status:

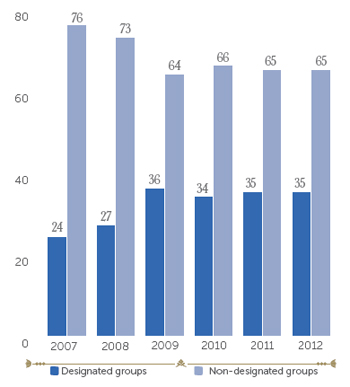

Percentage of staff from designated groups as defined by the Department Labour

5. Employment equity and transformation

Clover submits employment equity reports and plans as required by legislation. Communication and consultation with relevant stakeholders takes place on a regular basis. Steady progress has been made to increase the number of people from designated groups (as defined by the Department of Labour) at management level.

5.1 Employment equity plan: 2012 to 2014

Subsequent to a review conducted by the Department of Labour in terms of section 43 of the Employment Equity Act, 1998 it was established that Clover complies procedurally with the act, but lacks in achieving numerical goals.

Clover has finalised its employment equity plan, which commenced on 1 July 2012 and will continue up to 30 June 2014. The objectives of the plan are to give effect to the company’s employment equity policy in so far as it relates to employment equity goals. The employment equity plan will also ensure that Clover’s workplace remains free of unfair discrimination and reasonable progress is made towards employment equity in the workplace.

The Executive Committee is responsible for the implementation and monitoring of Clover’s employment equity plan. The committee, in execution of its duties, will assign specific responsibilities to individuals and managers in general. The responsibility to implement employment equity plans at the different Clover workplaces is delegated to site managers.

5.2 Affirmative action measures and strategies

Numeric goals and targets

To improve diversity in the workplace, and specifically to address the levels of representation of people from designated groups, Clover has committed to achieving the goals set out below:

| Objectives | Actual 31 May 2012 |

Target 30 June 2013 |

Target 30 June 2014 |

|---|---|---|---|

| Black people on F Band | 0% | 14.2% | 14.2% |

| Black people on E Band | 5,5% | 5,0% | 9,5% |

| Black women on E Band | 0% | 0% | 4,7% |

| Black people on C5 – D5 | 16% | 17,9% | 20% |

| Black women on C5 – D5 | 3,8% | 4,8% | 6,7% |

| Black people on C1 – C4 | 49,8% | 51% | 52,4% |

| Black women on C1 – C4 | 9% | 9,9% | 10,6% |

| Disabled people | 0,77% | 0,77% | 0,85% |

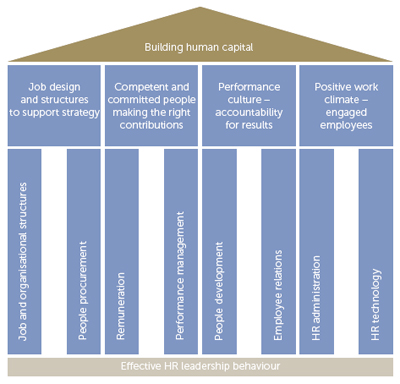

6. Human capital development

The contribution of the human resources function

To secure Clover’s position as one of Southern Africa’s leading fast moving consumer goods companies, the Company has adopted a proactive approach through its Clover Way Better™ initiative that extends all areas of its business such as procurement, production, marketing, sales and distribution and quality. At the basis of all these activities are people.

To be the ‘best team’ Clover recognises that its people will need to have higher levels of speed, passion and commitment. A company culture has to a large extent been created where employees commit to each other and to the Group’s vision and objectives.

Through Project Modellare Clover initiated a process which had as its primary aim the re-alignment of the human resource in the business, enabling employees to play an even bigger role to the advantage of Clover’s shareholders and to the community at large.

Project Modellare was conducted through extensive consultations with employees at management level with the following objectives in mind:

- Alignment of job content to strategy.

- Suggestions for improving alignment.

- Whether accountabilities are clear.

- Identify frustrations and stumbling blocks to achieving objectives and realising full potential.

- Personal career aspirations.

- Development needs.

- Personal circumstances affecting productivity and career plans.

Some of the outcomes from the engagement project that were identified include:

- The need to introduce a further retention mechanism for highly specialised and scarce skills (Category 'S' employees). Clover is in the process of identifying these positions and individuals.

- Roles have to be clarified.

- A further demonstration of openness and participation at senior management level is required.

- A social contract between the company and each employee exists and should be strengthened.

6.1 Training and development

To meet the business’ current and future requirements it is important that it unlocks the potential of all of its people. Individual aspirations are supported by purposeful and focused training and development while attending to realistic and equitable career planning. Speed of execution, passion and commitment are encouraged at all levels, as Clover believes that these give the Company a competitive advantage, and make it an employer of choice.

To this end, Clover has embarked on a workforce modernisation programme with the purpose of meeting the current performance and future growth objectives of the business and by regarding Clover’s human resources as an asset rather than expense. The key is to ensure that our people are a competitive advantage with an understanding of their role in ensuring the future sustainability of Clover’s workforce by seeking to identify ways to continually improve the performance of the business.

The Modernisation Programme will be effected through talent development initiatives, the Employee Assistance Programme, management and leadership competence development as well as functional job and technical training. The programme supports the National Skills Development Strategy, allowing the opportunity to access the Food and Beverages Sector Education and Training Authority ("Foodbev SETA") grant funding and also qualifies for tax incentive deductions. Qualifications are offered to employees through learnerships as part of the workforce Modernisation Programme.

Focused employee training and development, driven by powerful leadership, is a key business strategy to support Clover’s performance and growth objectives and to position the Company as the industry’s employer of choice.

ning and development focuses on firstly building competence that will ensure effective execution of operational tasks, and secondly on generating capacity in human resources that will ensure sustainable performance and growth.

These initiatives are supported by a well-structured formal approach to performance management.

Establishing a powerful and sustainable leadership pipeline of talented employees with the required competence and readiness to perform now and in the future is vital to Clover’s success.

In the past year, 3 827 learning opportunities were provided to 2 224 Clover employees. 1 842 (82.8%) of the employees were historically disadvantaged South Africans of which 382 (20.7%) were women. The focus is on these categories of employees as Clover must significantly bolster its levels of skilled employees from these designated groups, especially black people and women.

| Employee indicators | 2012 | 2011 | 2010 | 2009 | 2008 | ||

|---|---|---|---|---|---|---|---|

| Average number of employees | 6 555 | 6 353 | 6 362 | 6 579 | 6 662 | ||

| Employee turnover per year (%) | 8,21% | 10,9% | 9,3% | 10,3% | 10,6% | ||

| Number of man days lost due to strikes* | 346 | 112 | 334 | 415 | 0 | ||

| Total training spend per year (R’000) | 4 879 | 3 450 | 3 942 | 7 017 | 7 861 | ||

| Training spend per employee per year (R) | 744 | 565 | 665 | 1 066 | 1 180 | ||

| Number of employees trained | 2 224 | 2 058 | 1 550 | 3 133 | 5 928 | ||

| Number of man days spent on training | 2 965 | 2 744 | 2 067 | 4 177 | 7 904 | ||

|

|||||||

Clover’s Competence Development Model (“CDM”) was established to identify, develop and retain talented individuals to ensure a continuous pipeline of skills aligned with the business’ critical requirements. The CDM follows an integrated and holistic approach including the development of existing talent and sourcing external skills where appropriate. The model recognises the importance of developing both job technical competence as well as management and leadership capabilities.

7. Health and safety

Employees can only operate efficiently and effectively in a safe and healthy working environment. Given the perishable nature of Clover’s products, the Group closely monitors approaches to health and safety practices. Formal health and safety policies are in place as well as systems and processes to implement and monitor these. There is a standard health and safety procedure for every potentially dangerous substance or operation in the workplace.

All of the Group’s production facilities falling within the ambit of this report were audited by an accredited external party for safety during the year under review. Measures complying with ISO14000 (Environmental Management) and the Occupational Health and Safety Act (“OHS”) were used. Audits are conducted yearly to monitor continuous improvement.

The following results were achieved (as a percentage of compliance with OHS mentioned above):

| Site | Safety % |

|---|---|

| Frankfort | 85 |

| Heilbron | 86 |

| Clayville | 91 |

| Lichtenburg | 93 |

| Queensburgh | 94 |

| Estcourt | 89 |

| Bethlehem | 92 |

| Parow | 92 |

| Port Elizabeth | 98 |

| Mayfair | 92 |

Our aim is to achieve a 95% compliance rate over the next three years.

8. Environmental impact and strategy

Clover’s green initiative started in the prior financial year with the aim of establishing a formal environmental sustainability (“green”) strategy. As part of achieving this vision, Clover recognises its responsibility to reduce, and as far as practicable, to eliminate the impacts of its business on the environment. This responsibility relates not only to operations within Clover’s control, but also to Clover’s supply chain partners, which are recognised to be responsible for significant environmental impacts in supplying Clover.

In realisation of this responsibility, Clover is committed to the following objectives and outcomes:

| Objective | Outcome |

|---|---|

| Continuously improve on environmental performance. | Implement and maintain an effective environmental management system (“EMS”). Provide a structured framework for continual improvement. |

| Reduce carbon footprint. | Quantify the carbon footprint associated with operations and key elements of the supply chain. Set annual targets for reducing Clover’s overall climate impact. |

| Reduce water usage across operations. | Monitor water usage and set targets for reducing water consumption. |

| Limit the generation of solid and liquid wastes and the impact of their disposal. | Implement programme, monitor waste sent to landfill and set targets for reducing waste to landfill. |

| Minimise returns and damages and the impact thereof on the environment. | Implement programmes and monitor. |

| Reduce energy consumption and associated emissions. | Monitor energy usage and set targets for reducing consumption. |

| Manage impacts for on-site storage of fuels and chemicals, both during normal operation and in the event of spills and emergencies. | Implementation and monitoring of procedures. |

| Optimise the use of primary and secondary packaging. | Monitor wastage and implement improvement processes and targets. |

| Adhere to all applicable environmental legislation. | Continuously review and revise the ambit and effectiveness of the EMS. |

| Ensure continuous monitoring of and reduction in the impacts associated with milk supply. | Support and development of the Best Farming Practices Programme. |

| Inform supply chain partners on activities to reduce environmental impact and partner with them to reduce their own impact. | Formally engage with partners in the supply chain. |

| Inform staff on the EMS and policy and equip them with skills to achieve requirements of the policy. | aff engagement, formal development and training. |

Clover is committed to reviewing this environmental policy annually, as well as reviewing targets and progress towards achieving its environmental objectives. To enhance environmental awareness among staff, a Clover green section was introduced as a regular feature in the bi-monthly staff newspaper (In Clover), containing news on Clover’s green initiatives, staff involvement and clean-up challenges across the Group and providing green tips.

Amongst numerous other indicators, Clover actively monitors the following aspects through its use of the dedicated Entropy risk management system and various checks and balances.

| Working towards zero-waste operations | 2012 kg |

2011 kg |

Reducing the Group’s energy consumption | 2012 | 2011 | |

|---|---|---|---|---|---|---|

| Total waste generated by operations that was recycled | 1 188 047 | 829 377 | Electricity consumed per kg/lt product produced | 0,1471 kWh/kg | 0,1567 kWh/kg | |

| Total of all waste generated by operations that could be reused (either reworked or repacked) or used by a third party | 52 836 000 | 3 756 377 | Fuel consumed for steam generation (coal, gas HFO) per kg product produced | 0,4067 lt | 0,3921 lt | |

| Total waste product generated by all operations that was disposed of as animal feed | 4 095 553 | 2 927 073 | Constantly improving the Group’s occupational health and safety performance | 2012 lost time injury (man days) | 2011 lost time injury (man days) | |

| Reducing the amount of water used to produce the products | 2012 | 2011 | Incidents and injury reports throughout the Group’s operations | 574 | 579 | |

| Water consumed per kg of litre of product produced | 3,5 lt | 3,7 lt; |

Subsequent to Clover’s successful capital raising and listing on the Johannesburg Stock Exchange in December 2010, Clover commenced with the implementation of value-enhancing expansion and optimisation projects to increase the efficiency of the business platform and create capacity to support current and future growth of the business.

Clover’s primary capital project is named Project Cielo Blu. The intention behind Project Cielo Blu is to invest in the production and distribution infrastructure of the business to, inter alia: redress historical inefficiencies in the supply chain network resulting from the pre-1994 regulatory environment.

This will see the relocating of Clover’s production facilities to the milk source. Clover’s tankers haul approximately 650 million litres of raw milk per annum from the source to its production facilities. An approximate 16 million kilometres are covered on an annual basis to transport milk. This is partially done by third party transport, but Clover’s own vehicles are consuming more than six million litres of diesel, to fulfil this task.

Improved production and distribution efficiencies will have a marked impact on the transport of raw milk. Production at source implies that finished product will be distributed from the source area, which does not require the same specialised refrigeration technology and allows for better efficiency of the transport utilised, as an additional load can be scheduled for the return leg of the journey.

Project Cielo Blu will be phased in over a four-year period (commencing in 2011) and its associated benefits is expected to increasingly generate significant benefits and savings for the Group.

Clover is in the process of implementing measures to monitor its carbon footprint and anticipates Project Cielo Blu to gradually reduce the impact thereof. Full implementation is expected to be completed by November 2012.

9. Corporate social and community investment

Clover Mama Afrika is based on a simple concept. Clover empower community caregivers with viable skills, which they in turn pass on to others, in order to earn a sustainable income for the community. All of this is done whilst caring for society’s most vulnerable members, like orphaned and abused children, HIV Aids victims and neglected senior citizens.

Clover Mama Afrika continues to be an exemplary corporate social development initiative. Its infrastructure and tangible results have attracted several blue chip financial partners enabling the project to assist with various self-help projects. Another highlight for the project was winning the prestigious Proudly SA Homegrown – CSI Champion of the Year Award in 2011.

Since its inception in 2004, Clover Mama Afrika has grown to assist 35 remarkable Mamas across the country. These Mamas collectively had a positive impact on well over 12 800 children and more than 3 500 elderly.

Clover Mama Afrika candidates are identified on the following criteria:

- They have already started a nurturing and protective environment for the people they care for.

- They have managed a care centre for between three and five years.

- They have an existing dwelling that accommodates their work.

- Their work receives the respect and endorsement of the community.

- They are positively committed to job creation.

- They are willing to receive training and are committed to passing their newfound skills to recreate new jobs.

Clover Mamas are trained in essential skills like cooking, baking, sewing, crocheting, business management, food gardening and bread baking. They also receive the necessary tools, skills, training equipment and infrastructure to create an income for their communities, using their newly acquired skills.

9.1 Skills selection

From the onset of signing up a Clover Mama Afrika, this corporate social investment (“CSI”) initiative selected various skills training and development projects that ensure that the centres become self-sustainable. Great care goes into selecting the skills training that each Mama requires within their respective communities.

With all skills training offered, start-up equipment is given in order for them to implement their newfound skills straight away. It also gives the immediate opportunity to generate income and transfer the skills to other fellow community members.

9.2 Site improvement

In addition to the empowering projects, we assist with repairs and renovations of their premises. Even though property and building is not our main focus, we want to ensure that their physical environment is improved and has the basic facilities such as appropriate ablution facilities for health and hygiene purposes and that it is a safe haven for the members in their care. We also provide centres with the building of project houses where necessary. In the case of Mama Albertina of Alexandria, we secured a property for her to have a permanent centre for the disabled members she cares for.

9.3 Monitoring and evaluation

The hands on approach and close working relations with each of the Mamas ensure the regular monitoring and evaluation of each self-help project implemented. Through this evaluation process, we are able to identify the strengths and weaknesses/challenges on an individual basis. Immediate support and assistance is provided. The continued support from top management, Clover Branch personnel and external partners is also a positive attribute to the growing success of Clover Mama Afrika.

9.4 Sustainable impact as at 29 February 2012

| Skills training | Clover Mamas/ members trained | Operating Clover Mama Afrika centres | Skills transferred to fellow community members | Employed members earning wages/ salaries | ||

|---|---|---|---|---|---|---|

| Sewing | 102 | 28 | 364 | 70 | ||

| Bread oven project | 336 | 29 | 748 | 95 | ||

| Cooking and baking | 67 | 27 | 365 | 44 | ||

| Food gardens | 519 | 26 | 279 | 37 | ||

| Quilting | 18 | 12 | 113 | 14 | ||

| Crochet | 21 | 21 | 138 | 18 | ||

| Pottery | 1 | 1 | 20 | 2 | ||

| Added value skills training | ||||||

| Art | 39 | 31 | 7 | 2 | ||

| Flower arrangement | 37 | 28 | 197 | 15 | ||

| Mobile phones | 78 | 30 | ||||

| MKI health Information | 18 | 18 | Reach 20 000 + | |||

| Save a Child | 175 | 13 | ||||

| Basic admin/finance | 27 | 27 | ||||

|

||||||

9.5 Sustainable skills and needs analysis for the period 2012 to 2014

Clover Mama Afrika has positioned itself as a successful award winning example of an honest, sustainable and effective CSI project, which is making a real difference in the lives of many South Africans.

10. Future

Clover is cognisant of the fact that integrated reporting is a phased approach, which only started in 2009 for the Group. It also recognises the importance of avoiding a tick-box mentality, but to incorporate integrated reporting as part of Clover’s core. To this end, the committee can report that the Group has already started to see benefits from its integrated reporting process.

The Group has embarked on a process of collecting, collating and reporting key sustainability performance data, yet additional performance data – either for specific indicators, or for specific operations/locations – remain required to enhance the overall quality of Clover’s sustainability reporting.

The Group remains committed to continuous improvement in all matters that affect the sustainability of the Group and its activities.

Tom Wixley

Chairman

6 September 2012