MANUFACTURED CAPITAL OUTCOMES

|

OUR MANUFACTURED CAPITAL GREATLY ASSISTS US IN FACILITATING VALUE CREATING ACTIVITIES, AS THE QUALITY OF OUR MANUFACTURED CAPITAL DETERMINES THE QUALITY OF OUR PRODUCTS AND SERVICES. Along with the manufacturing of our products, Clover also has agreements with several major customers, for whom we provide distribution and in-store merchandising services |

FOCUS AREAS FOR 2018

| Supply chain planning and procurement | |

| Production efficiencies | |

| Product quality and food safety | |

| Distribution | |

| Masakhane |

HEALTH AND SAFETY AT CLOVER’S PRODUCTION FACILITIES

| Description | 2018 | 2017 |

| Fatalities – People working under our control | 0 | 0 |

|---|---|---|

| Total number of recordable injuries, including medically treated cases, lost time injuries (LTI) and fatalities | 37 | 83 |

| First aid cases – persons working under our control | 79 | 38 |

| Reportable (Compensation Commissioner) lost time injuries for this financial year | 26 | 45 |

| Fatal injury frequency rate (i.e. number of fatalities per 200 000 person hours worked) | 0 | 0 |

| Lost time injury frequency rate (i.e. the number of LTIs per 200 000 person hours worked) | 4,07 | 2,56 |

INPUTS

| Inputs | Change | 2018 | 2017 |

| Total production facilities | (6.7%) | 14 | 15 |

|---|---|---|---|

| Total trucks | 21.95% | 722 | 592 |

| Total distribution delivery points | 51.55% | 46 810 | 30 887 |

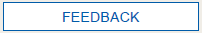

| Factory machine availability | (0.4%) | 98.2% | 98.6% |

| Capital expenditure on expansion or replacement of assets | (32.5%) | R214.7 | R316.8m |

OUTCOMES

| Supply chain efficiency projects, whereby juice production was consolidated in Gauteng, while fresh milk production was consolidated in Natal | ||

| A state-of-the-art planning software system is being used by the supply chain planning department | ||

| Product reformulations, driving cost efficiencies and optimised packaging | ||

| Clover has maintained a high level of factory machine availability | ||

| Supply quality control programme is in place to ensure compliance with international recognised foods safety requirements | ||

| Clover has a total of 24 distribution centres throughout the country | ||

| 19 962 new Masakhane customers in the current year | ||

| Total depreciation and amortisation of R228.5 million |

MATERIAL TRADE-OFFS

Investment in our production facilities and processes will positively impact our manufactured capital, however, this will negatively impact our financial capital.

A positive impact on our manufactured capital will also positively impact most of our capitals, such as building up our Intellectual capital and our human capital through upskilling and creating opportunities for our employees.

ACTIONS TO ENHANCE OUTCOMES

Clover leverages our industry leading distribution system to provide sales and distribution services to a number of multinational companies with the objective of:

- Optimising the distribution network through real time monitoring of execution

- Improving distribution mobility by delivering a paperless system to promote streamlined product returns and driver reconciliations

- Distribution retailer centralisation

- Expanding basket of principal products through strategic partnership focus

- Collaborating with principal customers and retailers

Improved alignment between operations, commercial and marketing will be achieved through enhanced communication and visibility planning.

THE FOCUS AREAS UP CLOSE

| Supply chain planning and procurement | |

Clover’s Supply Chain Planning Department centrally plans all manufacturing, purchasing, storing and deployment of finished goods throughout Clover’s integrated supply chain. Production requirements, stock levels and deployment plans are based on predicted future market demand for Clover’s products. Consumer demand is predicted through a sales and operations planning process that utilises statistical forecasting models as the baseline. These results are further checked in collaboration with Clover’s Commercial and Marketing divisions. The Supply Chain Planning Department is also responsible for managing all primary transportation between factories and distribution depots, as well as bulk deliveries to selected customers. Clover’s Centralised Procurement Department is responsible for procuring ingredients and packaging materials from qualifying suppliers including DFSA for raw milk, to provide consistent high-quality materials for production. Clover’s procurement philosophy is to build partnerships that shift the understanding beyond monetary considerations to also include socioeconomic objectives and long-term value creation. |

|

| Production efficiencies | |

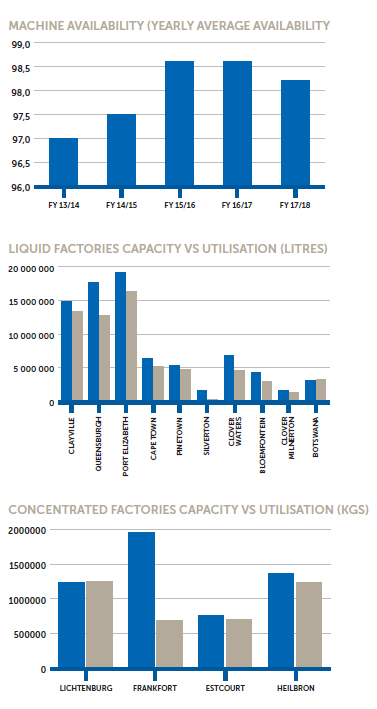

Factory machine availability: Maintaining a high level of machine availability is vital for achieving higher throughput per hour, reducing product losses and reducing energy consumption. A further benefit is that assets are properly utilised, and the need for additional equipment to accommodate a higher level of production is reduced when availability improves. Clover’s machine availability averages have increased substantially over the past five years. Depreciation vs capital expenditure: The quality of Clover’s manufactured capital will deteriorate if we do not continually invest in it. Clover invests to improve efficiency and effectiveness as opposed to maintaining assets. In the first two years of the three-year period shown, we allocated substantial capital resources to enhance the quality of our manufacturing assets. Capacity utilisation: Sales growth is only possible if the manufacturing capacity exists to meet the higher volumes of production required. Clover’s ability to manage manufacturing capacities is vital for ramping up to meet unexpected demand, or to reduce production when needed to keep unit production costs down. Clover’s capacity utilisation per product group must remain within best practice parameters. Milk intake is seasonal, with an increased milk intake between August and January in any given year, so that certain factories work at full capacity in the seasonal peak cycle. Production reduces substantially in the lower-milk flow season. Clover’s capacity during the seasonal peak determines limits for increased milk intake. As some products are highly seasonal, the average value and the peak (October) value have been utilised as being the most illustrative. |

|

| Product quality and food safety | |

All Clover products are produced according to international best practice standards for quality, hygiene and food safety. Products are only formally released by the Quality Control Department once assessed against these specifications. All of Clovers’ factories in South Africa are HACCP certified and accredited by third party auditors. We comply with all international standards required for food safety and quality risk management systems. Clover Quality Assurance and Control deploys highly trained technicians in well-equipped laboratories to test our products at all production stages. Clover implemented the latest and worldwide accepted FSSC 22000 quality management system and also introduced a supplier quality control programme to ensure that all raw materials and packaging materials comply with internationally recognised food safety requirements. |

|

| Distribution | |

Clover’s Primary Distribution Department moves all our products from factories to distribution facilities across South Africa. Every day, our customer call centre receives electronic or telephonic customer orders and arranges deliveries from one of Clover’s 24 distribution centres to approximately 46 810 delivery points in South Africa. |

|

| Masakhane – Let’s build together | |

Masakhane (literally meaning “let’s build together”) was initiated in 2012 as Clover’s first targeted approach to informal (emerging market) trading environments. The Masakhane objective is to grow the “emerging market” customer base and revenue stream by selling to stores that do not form part of a Clover key account or buying group. Masakhane has enabled Clover to rapidly increase our reach and footprint into informal and formal food service industry (FSI) trading systems such as spaza shops, tuck shops, corner cafés, general traders, hotels, schools, B&B, restaurants and bottle stores. Masakhane aims to create 1 004 new and permanent jobs within the distribution and informal retail sector by reaching 61 603 customer stores by 2020. Masakhane recruits undergo sales, marketing and distribution training that equip Masakhane entrepreneurs with the ability to carry out their daily responsibilities, while preparing and developing them for formal trade. Furthermore, Masakhane provides training directly to the informal store owners to equip them with the required commercial and supply chain expertise to further develop and sustain their stores. Masakhane contributes to alleviating unemployment in South Africa as it is a catalyst for growth and job creation. The Masakhane sales channel has evolved from a strictly informal trade focus to now include the formal and informal FSI sales channel. The results have been so successful that Clover Masakhane has expanded into the Swaziland and Namibia, where Clover has a sales and distribution infrastructure presence and “route to market” footprint. |

|

Natural capital

Natural capital