NATURAL CAPITAL OUTCOMES

|

NATURAL CAPITAL IS THE ENVIRONMENTAL RESOURCES USED BY THE COMPANY IN ITS VALUE CREATION PROCESS. CLOVER IS HEAVILY RELIANT ON NATURAL RESOURCES WHICH PLAY A VITAL ROLE IN OUR VALUE CREATION PROCESS. We rely on land, water and agricultural crops in the production of our products. Our farmers are dependent on livestock to produce the milk that we purchase from them, and electricity is needed to run our operations. Clover recognises our responsibility to reduce or even eliminate the impacts of our business on the environment. This responsibility relates not only to Clover’s direct operations, but also to our supply chain partners and their environmental impacts. |

FOCUS AREAS FOR 2018

| Energy consumption | |

| Waste produced | |

| Water consumption | |

| Carbon footprint |

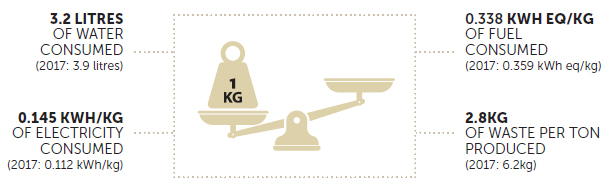

INPUTS AND OUTPUTS PER KILOGRAM OF PRODUCT PRODUCED

INPUTS

| Inputs | Change | 2018 | 2017 |

| Total water consumption (kilolitres) | 2.62% | 2 782 553 | 2 711 524 |

|---|---|---|---|

| Total direct energy consumption (ie fuels) (Gigajoules) | -36.22% | 900 194 | 1 411 596 |

| Total indirect energy consumption (ie electricity) (Gigajoules) | -12.89% | 387 647 | 445 027 |

| Sugar, fruit, milk, water, wheat |

INPUTS

| Outputs | Change | 2018 | 2017 |

| Total weight of non-hazardous waste disposed (ton) | -1.56% | 4 299 | 4 367 |

|---|---|---|---|

| Total weight of hazardous waste disposed (ton) | 10.53% | 4.2 | 3.8 |

| Total weight of waste sent for recycling (ton) | 482.13% | 20 322 | 3 491 |

| Total Carbon Emissions (tons of carbon dioxide equivalents, CO2e) | -11.00% | 210 971 | 237 059 |

| Total Scope 1 Emissions (tons CO2 eq) | -9.22% | 105 536 | 116 253 |

| Total Scope 2 Emissions (tons CO2 eq) | -12.73% | 105 434 | 120 807 |

| Carbon intensity (tonnes CO2e per ton produced – based on scope 1 and 2 emissions) | -28% | 0,249 | 0,346 |

OUTCOMES

| Boiler combustion optimisation to focus on improved electrical efficiency technology. | ||

| Initiative to recycle and re-use waste, organic waste is sent to a biomass plant. | ||

| We have reduced the average water consumption per kg of product produced to 3.2 litres from 3.6 litres in the previous year. | ||

| We have reduced our total carbon emissions by 11% from the prior period. | ||

| Woodchip boilers are being investigated, to reduce the use of the carbon intensive coalbased boilers. | ||

| An environmental management system has been implemented, and Clover’s production division is now certified as compliant with ISO 14001:2015. |

MATERIAL TRADE-OFFS

The emissions and waste from our production processes have a negative impact on natural capital, however the production processes of creating valueadded products will ultimately result in an increase in financial capital and value for our stakeholders.

There is also a decrease in Clover’s financial capital as we invest in improving our processes, to minimize the impact of our operations on natural capital.

FUTURE OUTLOOK

Clover intends partnering with specialist service providers to ensure economies of scale through new technologies that will make Clover the efficiency leader in our market segments. Projected efficiencies include eliminating waste to landfill and effluent initiatives, among other environmental impacts. Clover’s end-goal is to create long term and sustainable value through good corporate citizenship.

The beneficiation of organic waste to generate energy will be further investigated to reduce Clover’s impact on the environment.

Clover is evaluating power generation through solar photovoltaics at six of its factories.

Human capital

Human capital